Practices – Ship

Available to Promise (ATP)

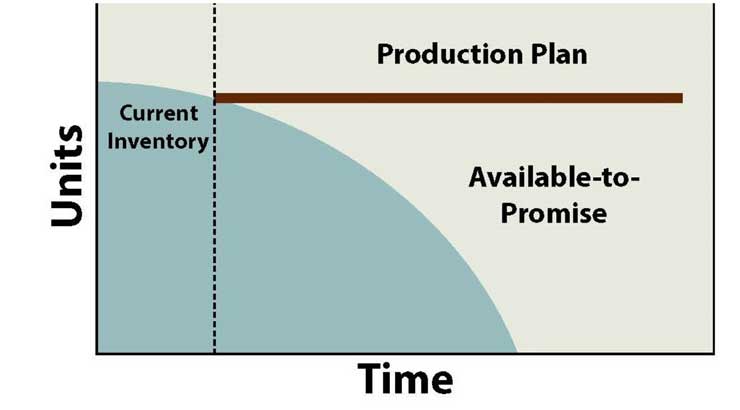

We implement Available to Promise (ATP) functionality to accurately track and manage inventory levels and order fulfillment capabilities. ATP provides real-time visibility into inventory availability, order commitments and scheduled receipts ensuring that customers receive timely and accurate delivery information. By effectively managing ATP, we reduce the risk of overpromising and underdelivering, leading to improved on-time delivery performance and enhanced customer satisfaction.

60% of Supply Chain Professionals Answered this Question Incorrectly - Customers Beware!

I recently created this quiz on Linkedin about when to utilize Available to Promise (ATP) functionality. Out of 52 votes, only 38% selected the correct response, which suggests that there is a definite knowledge gap on this important topic.

I recently created this quiz on Linkedin about when to utilize Available to Promise (ATP) functionality. Out of 52 votes, only 38% selected the correct response, which suggests that there is a definite knowledge gap on this important topic.

ATP functionality can be highly effective when used correctly. In a previous article, I do a deeper dive into how ATP works. In this article, I’ll focus on explaining the quiz results.

Read More…

60% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

60% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

One Key Practice to Help Build Trust with Your Customers

If we assume that the ability to deliver the perfect profitable order is the primary goal of any supply chain, then the ability to accurately predict when a customer order will be available is clearly an important capability. For make to stock (MTS) environments, this functionality is called Available to Promise (ATP), and Capable to Promise (CTP) in a make to order (MTO) environment. Here is how they work

If we assume that the ability to deliver the perfect profitable order is the primary goal of any supply chain, then the ability to accurately predict when a customer order will be available is clearly an important capability. For make to stock (MTS) environments, this functionality is called Available to Promise (ATP), and Capable to Promise (CTP) in a make to order (MTO) environment. Here is how they work

Read More…

One Key Practice to Help Build Trust with Your Customers

One Key Practice to Help Build Trust with Your Customers

Daily Visual Management

Our approach to daily visual management involves using visual tools and dashboards to monitor and manage daily operations. By making key performance indicators and workflow status visible to all team members, we ensure that issues are quickly identified and addressed. This proactive approach enhances coordination and responsiveness, leads to more reliable on-time deliveries and improved operational efficiency.

Daily Visual Management

As COVID-19 has so clearly reminded us, supply chains are inherently dynamic! No doubt you experience unplanned events on a regular basis, such as sudden demand changes, canceled customer orders, inbound shipment delays, supplier quality issues, etc.

As COVID-19 has so clearly reminded us, supply chains are inherently dynamic! No doubt you experience unplanned events on a regular basis, such as sudden demand changes, canceled customer orders, inbound shipment delays, supplier quality issues, etc.

In addition, you will also be all too familiar with miscommunications between departments, causing delays and missteps. For example, the quality group not prioritizing items needed to prevent production shutdowns, or purchasing placing a large material order for an item whose demand has just been drastically reduced due to its removal of the bill of material.

Read More…

Daily Visual Management

Daily Visual Management

Sales Order Date Management

We help our clients develop robust policies and procedures regarding the management and maintenance of customer order date, customer request date, original commit date, revised delivery date, and actual delivery date. All these dates help us enhance on-time delivery by aligning production and logistics with customer expectations. The customer order date and request date guide scheduling, while the original commit date sets performance benchmarks. The revised delivery date informs customers of any changes, and the actual delivery date allows us to measure our performance against commitments and assess fulfillment lead times.

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

I have found this topic to be excruciatingly difficult, given how simple it seems. I am referring to dates associated with a customer order, including order receipt date, order entry date, request date, original promise date, revised promise date, ship date, delivery date, etc. I may have been just unfortunate, but in my experience, most companies are not aligned on the definition of each date, and they do not manage them effectively. This is not a trivial matter. Without clarity here, we are unable to confidently answer some of the most basic supply chain-related questions:

I have found this topic to be excruciatingly difficult, given how simple it seems. I am referring to dates associated with a customer order, including order receipt date, order entry date, request date, original promise date, revised promise date, ship date, delivery date, etc. I may have been just unfortunate, but in my experience, most companies are not aligned on the definition of each date, and they do not manage them effectively. This is not a trivial matter. Without clarity here, we are unable to confidently answer some of the most basic supply chain-related questions:

Read More…