This page is located on our new website which is currently in development.

To visit our current site please click here.

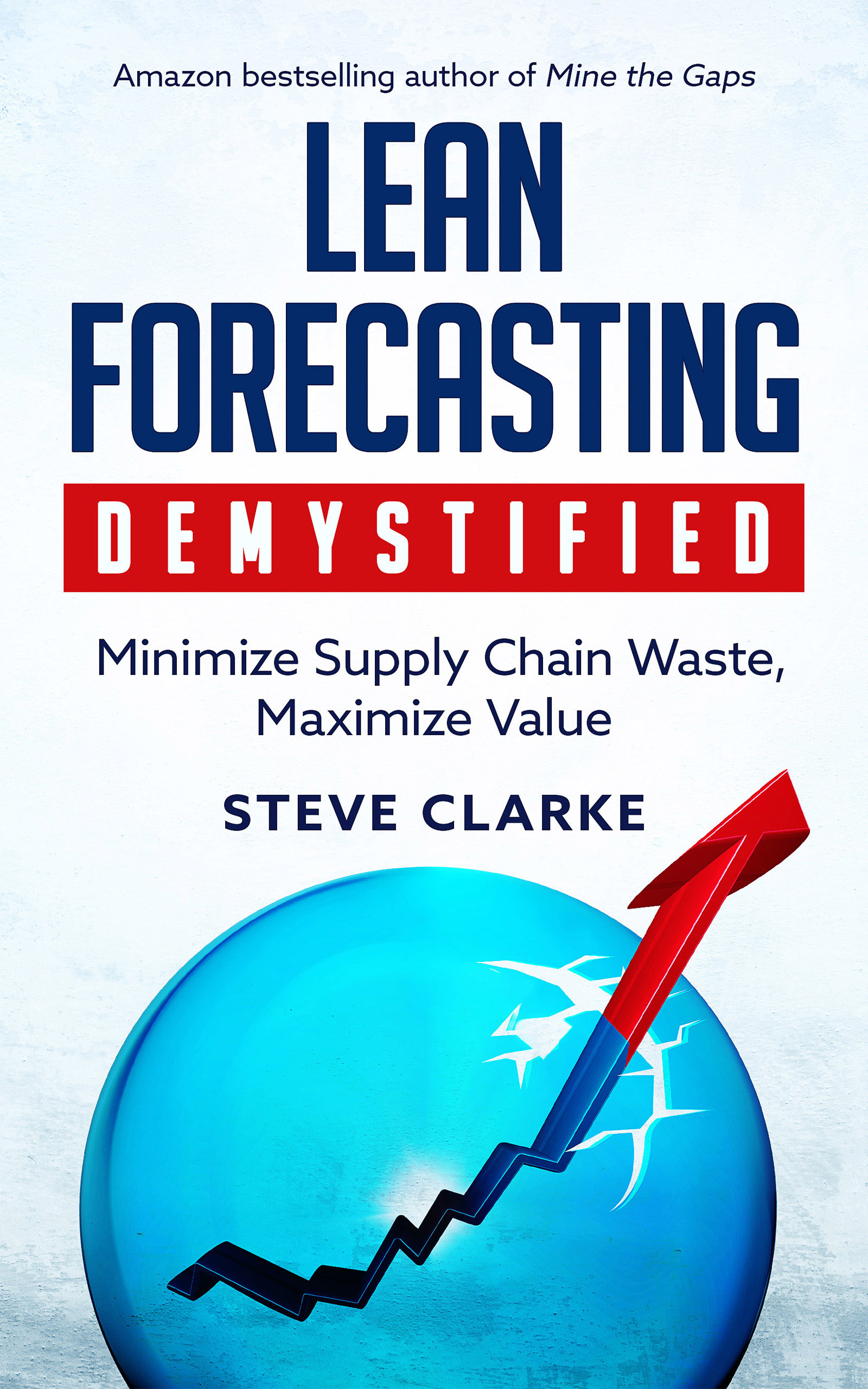

Lean Forecasting Demystified

Minimize Supply Chain Waste, Maximize Value

Struggling with a cumbersome forecasting process yielding unsatisfactory results? Lean Forecasting Demystified by Steve Clarke offers a transformative solution by applying lean principles to forecasting. Clarke delves into how the lean approach, renowned for its radical reduction of costs, lead times, and inventory within the manufacturing environment, can revolutionize forecasting.

This guide champions lean business forecasting, favoring practical tools over complex technology to enhance accuracy swiftly and affordably. Clarke’s accessible style, infused with humor and real-world examples, guides readers through optimizing forecasts, managing safety stocks, and reacting effectively to demand shifts.

With plentiful illustrations and actionable insights, Lean Forecasting Demystified empowers organizations to adopt lean principles, cutting waste, enhancing customer service, and boosting supply chain performance.

The articles below, published through LinkedIn, include some of the topics covered in the book.

Fix this 1 forecasting practice and improve your supply chain immediately and forever!

Forecast bias can lead to excess inventory or constant shortages—both costly mistakes. Unlike random variation, bias is induced by management practices and is completely avoidable. Learn how to identify and eliminate forecast bias to drive better performance and achieve more accurate results.

Forecast bias can lead to excess inventory or constant shortages—both costly mistakes. Unlike random variation, bias is induced by management practices and is completely avoidable. Learn how to identify and eliminate forecast bias to drive better performance and achieve more accurate results.

Read More…

Fix this 1 forecasting practice and improve your supply chain immediately and forever!

Are your Forecasts Doing More Harm than Good?

Is your forecasting process adding value or just creating more error? Forecast Value Added (FVA) measures the effectiveness of your forecasting efforts. If your current process isn’t outperforming a simple naive forecast, it’s time to rethink your strategy. Learn how FVA analysis can help streamline and improve your forecast accuracy.

Is your forecasting process adding value or just creating more error? Forecast Value Added (FVA) measures the effectiveness of your forecasting efforts. If your current process isn’t outperforming a simple naive forecast, it’s time to rethink your strategy. Learn how FVA analysis can help streamline and improve your forecast accuracy.

Read More…

3 Great Strategies to Minimize C Item Pain

C items generally contribute about 5% of revenue, even though they account for about 50% of our items. So, understanding an appropriate strategy for these items will certainly take complexity out of your supply chain.

C items generally contribute about 5% of revenue, even though they account for about 50% of our items. So, understanding an appropriate strategy for these items will certainly take complexity out of your supply chain.

Read More…

3 Great Strategies to Minimize C Item Pain

3 Great Strategies to Minimize C Item Pain

What the milkman can teach us about inventory management excellence

Read More…

What the milkman can teach us about inventory management excellence

60% of Supply Chain Professionals Answered this Question Incorrectly - Customers Beware!

Read More…

60% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

60% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

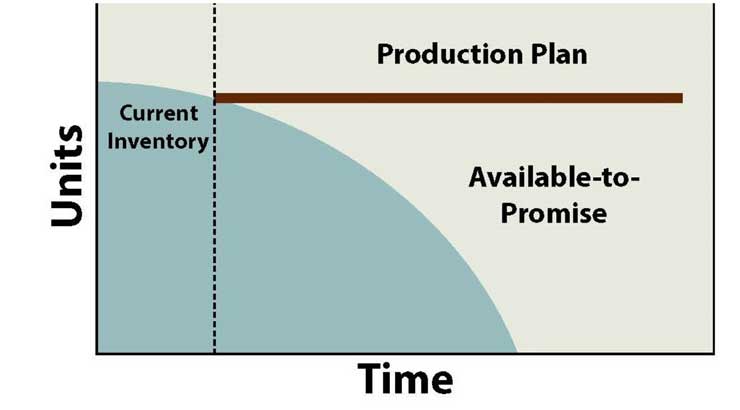

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

Read More…

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

Understanding "Good" and "Bad" Forecast Inaccuracy

Read More…

Understanding “Good” and “Bad” Forecast Inaccuracy

Understanding “Good” and “Bad” Forecast Inaccuracy

The 2 Biggest Errors in Forecast Accuracy You Didn’t Know You Were Making

Read More…

The 2 Biggest Errors in Forecast Accuracy You Didn’t Know You Were Making

"Make Everything as Simple as Possible, but not Simpler" - Albert Einstein

Read More…

“Make Everything as Simple as Possible, but not Simpler” – Albert Einstein

Forecasting Efficiency: Shifting from Item-Level to Product Family for Better ResultsUnderstanding "Good" and "Bad" Forecast Inaccuracy

Read More…

Forecasting Efficiency: Shifting from Item-Level to Product Family for Better Results

Forecasting Efficiency: Shifting from Item-Level to Product Family for Better Results

The Power of Demand Shaping: Reducing Volatility for Better Forecasts

Read More…

The Power of Demand Shaping: Reducing Volatility for Better Forecasts

Mastering Forecast Accuracy: Conquer Artificial Volatility for Supply Chain Excellence

Read More…

Mastering Forecast Accuracy: Conquer Artificial Volatility for Supply Chain Excellence

Part 3: Forecast Simplification - Keep It Simple Strategies (K.I.S.S)

Is your sales team spending too much time forecasting instead of driving revenue? Simplifying the forecast update process can help. From setting detailed forecast time fences to leveraging ABC item stratification, learn key strategies to improve forecast accuracy and focus on what matters most.

Is your sales team spending too much time forecasting instead of driving revenue? Simplifying the forecast update process can help. From setting detailed forecast time fences to leveraging ABC item stratification, learn key strategies to improve forecast accuracy and focus on what matters most.

Read More…

Part 3: Forecast Simplification – Keep It Simple Strategies (K.I.S.S)

Part 3: Forecast Simplification – Keep It Simple Strategies (K.I.S.S)

What this Picture from Mars tells us about a Common Forecasting Mistake

Read More…

What this Picture from Mars tells us about a Common Forecasting Mistake

Choosing the Right Forecasting Strategy: Key Insights for Supply Chain Success

Read More…

Choosing the Right Forecasting Strategy: Key Insights for Supply Chain Success

This page is located on our new website which is currently in development.

To visit our current site please click here.

How a bad forecast and Mothers’ Day flowers almost cost me my job

How a bad forecast and Mothers’ Day flowers almost cost me my job There are many supply chain organizations that are quite unreliable when it comes to meeting their commitments as to when product will be available for their customers. Here is one practice that will help you earn that trust back.

There are many supply chain organizations that are quite unreliable when it comes to meeting their commitments as to when product will be available for their customers. Here is one practice that will help you earn that trust back.