Strategic Objectives

Capability Growth

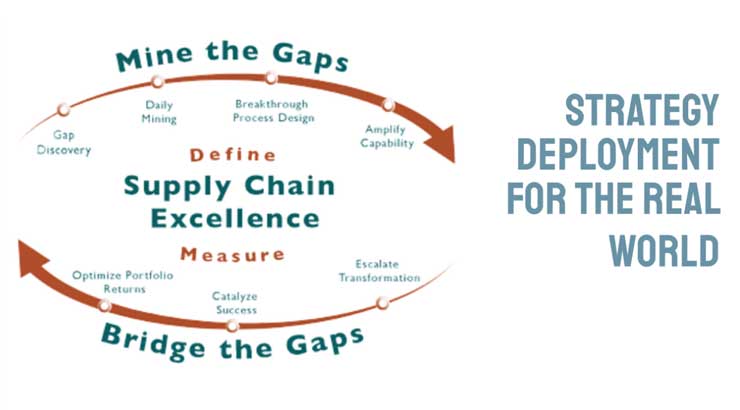

Leveraging strategic sourcing and process maturity models we support your expansion efforts by optimizing supply chain capabilities and enhancing operational scalability. Business process redesign and technology integration facilitate smooth growth and increased capacity.

My Capability Growth Project Summary

Number of Projects

37

Average % Improvement

54%

Average $ Improvement

$2m

Average ROI

95

My Capability Growth Related Articles

Mastering Forecast Accuracy: Conquer Artificial Volatility for Supply Chain Excellence

This is an excerpt from my new book, Lean Forecasting Demystified. If you find this valuable, please click on this link to place a preorder on Amazon.

This is an excerpt from my new book, Lean Forecasting Demystified. If you find this valuable, please click on this link to place a preorder on Amazon.

In 2004, director James Cameron said “Hope is not a strategy” when addressing the NASA Administrator’s Symposium. He was referring to his exploration of the Titanic wreck to which he has made thirty-three dives. Suffice to say “hope” did not play a large part in his planning process. In fact, his engineering team spent seven years building the submersible capable of performing this feat.

Read More…

Mastering Forecast Accuracy: Conquer Artificial Volatility for Supply Chain Excellence

Mastering Forecast Accuracy: Conquer Artificial Volatility for Supply Chain Excellence

Part 3: Forecast Simplification - Keep It Simple Strategies (K.I.S.S)

Challenge

Challenge

In many organizations, the task of creating a forecast has been made much more difficult than necessary. The sales team might be asked to provide monthly forecast updates for individual items for the next 12-24 months. This is a painful, time-consuming process, that takes the sales team away from revenue generation. In addition, attention is not paid to the critical few items that should be focused upon, thereby reducing forecast accuracy, which in turns will create excess inventory and product shortages, simultaneously.

Read More…

Part 3: Forecast Simplification – Keep It Simple Strategies (K.I.S.S)

Part 3: Forecast Simplification – Keep It Simple Strategies (K.I.S.S)

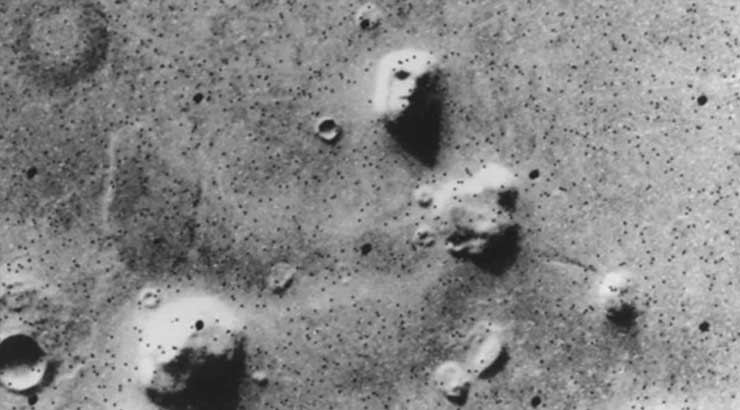

What this Picture from Mars tells us about a Common Forecasting Mistake

On July 25, 1976, the Viking 1 orbiter took a photograph of the Martian surface that included a formation resembling a face-like structure.

The photo created quite a stir back on earth with rumors that the face was evidence of life on Mars and that NASA was covering it up. Since then, it was featured in radio shows, talk shows, tabloid papers, books, and websites. Personally, I tend to lean towards NASA’s explanation that this was an example of pareidolia, a psychological phenomenon where the human mind perceives familiar patterns, shapes, or meaningful images in random or ambiguous stimuli. Their caption below the photo read: “The huge rock formation in the center, which resembles a human head, is formed by shadows giving the illusion of eyes, nose and mouth.”

Read More…

What this Picture from Mars tells us about a Common Forecasting Mistake

What this Picture from Mars tells us about a Common Forecasting Mistake

Choosing the Right Forecasting Strategy: Key Insights for Supply Chain Success

Demand Volatility/Variability

Demand Volatility/Variability

Firstly, it is critical to understand that more demand volatility translates to less accurate forecasts. For example, I grew up in Northern England and moved to California in my mid-twenties. For my first few years in California, I lived in the San Joaquin Valley (SJV). Immediately after I arrived, I noticed that the weather was very stable compared to England. I often thought about how different it must be for meteorologists in both places, especially during the summer. I would much rather predict the weather in the SJV than back in England.

Read More…

Choosing the Right Forecasting Strategy: Key Insights for Supply Chain Success

Choosing the Right Forecasting Strategy: Key Insights for Supply Chain Success

An S&OP Roadmap from Under-Performing to Excellence

Sales and Operations Planning (S&OP) aka Integrated Business Planning does not happen overnight. Many organizations claim to have implemented it, but a deep dive shows that it is a glorified (and expensive) expediting meeting. The chart below is from my supply chain maturity model showing the different elements to expect at each maturity level. Your challenge is to accurately diagnose the current level at your organization, to help what is required to get to the next level.

Sales and Operations Planning (S&OP) aka Integrated Business Planning does not happen overnight. Many organizations claim to have implemented it, but a deep dive shows that it is a glorified (and expensive) expediting meeting. The chart below is from my supply chain maturity model showing the different elements to expect at each maturity level. Your challenge is to accurately diagnose the current level at your organization, to help what is required to get to the next level.

It takes time, so it is helpful to have a roadmap to help guide you to the finish line.

Read More…

An S&OP Roadmap from Under-Performing to Excellence

An S&OP Roadmap from Under-Performing to Excellence

3 Questions to Ask Before you Start your Next Software Implementation

Read More…

3 Questions to Ask Before you Start your Next Software Implementation

3 Questions to Ask Before you Start your Next Software Implementation

Avoiding the Traps of Premature Dashboard Implementation

We all love the idea of sleek, sexy dashboards with gorgeous graphics that offer deep insights into our operational challenges and how to fix them. But let’s be honest, we often want these analytics faster than our organizations can handle. Sound familiar?

A prime example is a pharmaceutical client of mine who asked me to figure out why their project to develop a supply chain dashboard was endlessly delayed. The goal? Develop business analytics using outputs from their supply chain planning tool.

Read More…

Avoiding the Traps of Premature Dashboard Implementation

Avoiding the Traps of Premature Dashboard Implementation

Why are you still planning in Excel and what to do about it?

From my experience, the primary issue is quite simply that the implemented software does not meet planner requirements. We are wowed by sexy dashboards and control towers while forgetting to ask fundamental questions.

Read More…

Why are you still planning in Excel and what to do about it?

Why are you still planning in Excel and what to do about it?

How to avoid biting off more than you can chew on your next ERP project

Many of you have probably been through a major software implementation, such as ERP. You know the drill; knowledgeable employees are asked to create their wish list to share with the software vendors.

I have several concerns with this simplistic approach, but in my opinion, the biggest issue is that the onus is all on the technology. In other words, the software will be challenged on its ability to meet all the requirements, but the organization is not challenged on its own ability to meet the requirement from a process and data accuracy standpoint.

Read More…

How to avoid biting off more than you can chew on your next ERP project

How to avoid biting off more than you can chew on your next ERP project

2 Very Expensive Bad Measurement Practices

Read the excerpt from my book on LinkedIn:

Read More…

2 Very Expensive Bad Measurement Practices

2 Very Expensive Bad Measurement Practices

Three powerful ways to redesign your supply chain processes

Whenever you are evaluating a business process, every step should be challenged. Here are the 3 challenges that we will focus on today:

1. What? Could the step be completely removed from the process?

2. Who? Is the step performed by the correct person, or would it be more efficient or effective for someone else to perform the step?

Read More…

Three powerful ways to redesign your supply chain processes

Three powerful ways to redesign your supply chain processes

14 Questions to Assess your Supply Chain Capability

I have developed a capability model that describes the characteristics associated with different levels of supply chain capability. Below are the characteristics that describe a supply chain at the lowest capability level. If it sounds like they sound like they are describing your organization, then you probably already know that you are facing supply risk, and it is time to act.

Read More…

14 Questions to Assess your Supply Chain Capability

14 Questions to Assess your Supply Chain Capability

10 Ways to Ensure your Supply Chain Churns Out Mediocre Results

Ignore the real reason for your problems

Whenever a problem occurs, it is rare in my experience that management asks what is wrong with the business process design. Instead, they will tend to look for someone to blame. It is ironic because studies have shown that the root cause for 90% of business problems is poor business process design, which is the responsibility of management.

Read More…

10 Ways to Ensure your Supply Chain Churns Out Mediocre Results

10 Ways to Ensure your Supply Chain Churns Out Mediocre Results

7 steps to successfully commercialize your life science supply chain

Solution

Great process creates great results, and lousy process creates – you guessed it – lousy results. Here is a 7-step methodology to make it happen:

Read More…

7 steps to successfully commercialize your life science supply chain

7 steps to successfully commercialize your life science supply chain

Why Smart People do Dumb Things

Excerpt….

When companies decide to distort the data to achieve their targets, without actually improving anything it causes seemingly smart managers to feel compelled to do really dumb things to meet metric targets, such as:

Revenue targets

Sales managers who alienate key customers because they need to close a sale by the end of the month so they can get their quarterly sales bonus

Read More…

Why Smart People do Dumb Things

Why Smart People do Dumb Things

You Can’t Manage What You Can’t Measure… Well! 3 strategies to get more from your metrics.

Although Peter Drucker was correct in saying, “you can’t manage what you can’t measure,” that does not mean that you can necessarily “manage what you can measure”. Since measure is mostly a mess!

As the “Reengineering” guru Michael Hammer stated so accurately “A company’s measurement systems typically deliver a blizzard of nearly meaningless data that quantifies practically everything in sight, no matter how unimportant; that is devoid of any particular rhyme or reason; that is so voluminous as to be unusable; that is delivered so late as to be virtually useless; and that then languishes in printouts and briefing books, without being put to any significant purpose…”

Read More…

You Can’t Manage What You Can’t Measure…. Well! 3 strategies to get more from your metrics.

You Can’t Manage What You Can’t Measure…. Well! 3 strategies to get more from your metrics.

The one section of the charter that will make or break your project

I want to give you some insight into a recent successful implementation and one key learning from the project. Maybe your next time “in the chair” will involve fewer nightmares than previous experiences.

Read More…

The one section of the charter that will make or break your project

The one section of the charter that will make or break your project

Struggling with Supply Chain Issues? Discover This Game-Changing Solution

I think it is a safe guess that your organization is struggling to achieve at least one important strategic objective within your supply chain and operations. It is also probably safe to say that the obstacles are some combination of heavy workloads, wasteful practices, ill-defined and poorly designed business processes, inaccurate data, insufficient attempts to understand root causes, not working on the right projects, not managing projects effectively and ineffective metrics etc. etc. Am I wrong?

Read More…