Strategic Objectives

Delivery

Implementing MRP, inventory record accuracy and master scheduling ensures timely order fulfillment, improving delivery performance and customer satisfaction.

My Delivery Project Summary

Number of Projects

7

Average % Improvement

92%

Average $ Improvement

$1.74m

Average ROI

112

My Delivery Related Articles

Take Control of your Supply Chain with this Powerful Practice

Sometimes inventory can be allocated and shipped in the blink of an eye. This is fantastic and the warehouse gets kudos for being so efficient. However, what if that shipment will cause a stockout for an “A” item, and the next delivery is not anticipated for 2 months. Even worse, what if the customer that took the remaining inventory was a “C” customer, and the next day a strategic customer places an order for the same item?

Sometimes inventory can be allocated and shipped in the blink of an eye. This is fantastic and the warehouse gets kudos for being so efficient. However, what if that shipment will cause a stockout for an “A” item, and the next delivery is not anticipated for 2 months. Even worse, what if the customer that took the remaining inventory was a “C” customer, and the next day a strategic customer places an order for the same item?

Read More…

Take Control of your Supply Chain with this Powerful Practice

Take Control of your Supply Chain with this Powerful Practice

A Cautionary Tale about Forecast Inaccuracy

An excerpt from my new book: Forecasting Demystified

An excerpt from my new book: Forecasting Demystified

Prediction is very difficult, especially if it’s about the future! —Niels Bohr, Danish physicist

Night of the Long Knives

I came into work one morning to learn that most of the senior management team had been fired. In the following few months, everything was different at the company where I had worked for five years. The most tangible change was that the company closed the plush corporate office where I had worked. They gave me a choice: relocate to the manufacturing site or adios. Given that I had a wife and three kids settled in a lovely small town on the water, with many good friends, there was no desirable choice. In the end, we reluctantly relocated from the San Francisco area to be close to the manufacturing site in Southern California.

Read More…

A Cautionary Tale about Forecast Inaccuracy

A Cautionary Tale about Forecast Inaccuracy

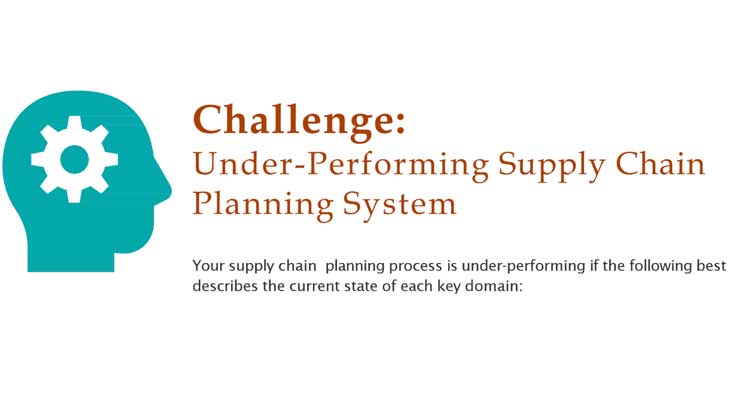

You Might Be Managing an Under-Performing Supply Chain Planning System if...

What is the capability level of your supply chain planning system? Check out my maturity model below for what an under-performing supply chain planning system looks like. Unfortunately, I’ve had more experience of under-performing supply chain planning systems, than performing ones.

What is the capability level of your supply chain planning system? Check out my maturity model below for what an under-performing supply chain planning system looks like. Unfortunately, I’ve had more experience of under-performing supply chain planning systems, than performing ones.

Read More…

You Might Be Managing an Under-Performing Supply Chain Planning System if…

You Might Be Managing an Under-Performing Supply Chain Planning System if…

0% of Supply Chain Professionals Answered this Question Incorrectly - Customers Beware!

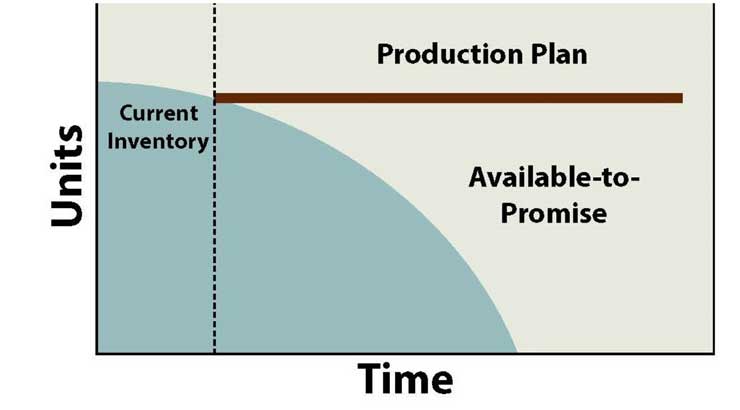

I recently created this quiz on Linkedin about when to utilize Available to Promise (ATP) functionality. Out of 52 votes, only 38% selected the correct response, which suggests that there is a definite knowledge gap on this important topic.

I recently created this quiz on Linkedin about when to utilize Available to Promise (ATP) functionality. Out of 52 votes, only 38% selected the correct response, which suggests that there is a definite knowledge gap on this important topic.

Read More…

0% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

0% of Supply Chain Professionals Answered this Question Incorrectly – Customers Beware!

One Key Practice to Help Build Trust with Your Customers

If we assume that the ability to deliver the perfect profitable order is the primary goal of any supply chain, then the ability to accurately predict when a customer order will be available is clearly an important capability. For make to stock (MTS) environments, this functionality is called Available to Promise (ATP), and Capable to Promise (CTP) in a make to order (MTO) environment. Here is how they work:

If we assume that the ability to deliver the perfect profitable order is the primary goal of any supply chain, then the ability to accurately predict when a customer order will be available is clearly an important capability. For make to stock (MTS) environments, this functionality is called Available to Promise (ATP), and Capable to Promise (CTP) in a make to order (MTO) environment. Here is how they work:

Read More…

One Key Practice to Help Build Trust with Your Customers

One Key Practice to Help Build Trust with Your Customers

Daily Visual Management

In addition, you will also be all too familiar with miscommunications between departments, causing delays and missteps. For example, the quality group not prioritizing items needed to prevent production shutdowns, or purchasing placing a large material order for an item whose demand has just been drastically reduced due to its removal of the bill of material.

Read More…

Daily Visual Management

Daily Visual Management

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

Read More…

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

Customers Want to Know When Will their Products Arrive. Why is it so difficult?

5 Ways to Take Control of your Ability to Ship On-Time

Challenge

In this shortage economy, many of you will be struggling to maintain on time shipments to your customers. However, I’m going to go out on a limb here and say that most of your supply issues are very much within your control, so it is time to take the bull by the horns!

Solution Here are 5 techniques that I have repeatedly utilized to improve on-time shipment performance:

Read More…

5 Ways to Take Control of your Ability to Ship On-Time

5 Ways to Take Control of your Ability to Ship On-Time

How to cut through the complexity and achieve your strategic objectives

Read More…

How to cut through the complexity and achieve your strategic objectives

How to cut through the complexity and achieve your strategic objectives

Take the Road Less Traveled to Quickly Achieve your Supply Chain Targets

Case Study

At one client that was challenged with low on-time shipment performance, I was asked to help them solve the issue. The goal was to improve from <70% to 95% on-time within one quarter. We did all the right things – formed a team, analyzed late order data and proposed solutions, with the following conclusions:

Read More…

Take the Road Less Traveled to Quickly Achieve your Supply Chain Targets

Take the Road Less Traveled to Quickly Achieve your Supply Chain Targets

Your first 2 steps to minimize supply risk and to reduce those sleepless nights!

Read More…

Your first 2 steps to minimize supply risk and to reduce those sleepless nights!

Your first 2 steps to minimize supply risk and to reduce those sleepless nights!

Operational Mediocrity Endangers Lives!

A child patient with a chronic condition requiring stomach tube feeding suffered due to an administrative oversight. The incorrect tube size prescribed caused irritation and inflammation, leading to prolonged discomfort. Despite repeated hospital visits, the issue persisted until a vigilant nurse identified the root cause.

Read More…

Operational Mediocrity Endangers Lives!

Operational Mediocrity Endangers Lives!

1 approach to quickly achieving on-time delivery that your patients hope you will learn

Read More…

1 approach to quickly achieving on-time delivery that your patients hope you will learn

1 approach to quickly achieving on-time delivery that your patients hope you will learn

Getting from Objective to Result as Quickly as the Crow Flies

For example, at one client, the objective was to improve customer service. We improved on-time delivery from below 80% to 95% in less than four months simply by monitoring late orders on a daily basis for a few weeks in a cross- functional team environment. This approach had much more alignment and harmony than if each department was investigating these issues in silos.

Read More…

Getting from Objective to Result as Quickly as the Crow Flies

Getting from Objective to Result as Quickly as the Crow Flies

How to win a game of Whack-a-Mole in your Supply Chain

Merely putting out the fire or whacking the mole is a Level 1 Fix. It is not very effective because you are only dealing with the symptom, not the root cause. It is like if you are continually having headaches, and just taking pain killers to make yourself feel better today, but not going to see your doctor to find out what is causing the headache.

Read More…

How to win a game of Whack-a-Mole in your Supply Chain

How to win a game of Whack-a-Mole in your Supply Chain

How to turn lemons to lemonade in any supply chain

- How to find “quick wins” to achieve your supply chain objectives within a quarter

- How to identify the projects that will ACTUALLY “move the needle”

- Which readily available data to leverage for success, and which data to ignore

- What specific data to analyze for virtually any supply chain objective

- When not to rely upon technology to achieve your objectives

- How to build organizational alignment for selected projects

Read More…